Large, double-acting (Figure 1), multicylinder, multistage crosshead design reciprocating compressors are used to generate low-pressure plant air, move natural gas in the natural gas production industry, supply high-pressure gas for oil well drilling, and for various applications in manufacturing or chemical processing that require medium- to high- pressure air. Because positive displacement screw compressors (Figure 2) are most common to industrial plant air requirements, this article focuses on gas transmission pipeline applications.

However, many of the issues pertaining to lubrication of reciprocating compressors for the pipeline application would also pertain to the effective lubrication of machines for in-plant service.

Gas transmission applications are typically powered by a reciprocating engine fueled by natural gas. These compressors may be located in the field at a remote station or at the inlet to a gas plant where raw, wet (containing droplets of water or hydrocarbon) and possibly sour (containing hydrogen sulfide, H2S) natural gas is compressed.

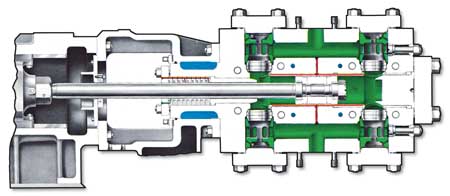

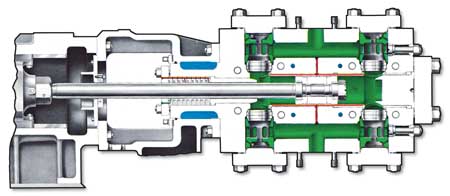

Figure 1. High-pressure Service, Forged-steel, Double-acting Cyclinder

The packing box is water-cooled. The packing may be oil- or water-cooled by a forced circulation system for maximum heat dissipation, depending on operating pressures. Tie bolts which run perpendicular to the cylinder base pre-stress high-pressure forgings, decreasing maximum tensile stress induced by gas pressure.

(Source: Dresser-Rand, Painted Post, NY)

They may also be located at the downstream end of a gas plant where totally clean and dry “sales” gas is compressed and moved into a pipeline system. In addition, reciprocating compressors are used for high-pressure gas reinjection into downhole reservoirs to enhance crude oil recovery. Centrifugal compressors (not discussed here) are typically used on natural gas pipeline systems to move large volumes of gas at lower pressures.

Compressor crankcase lubrication is relatively simple. Crankcase lubrication typically uses an oil system that is entirely separate from the compressor cylinder and rod-packing lube system. Natural gas engine oil is typically used because it is readily available if the drive, that powers the compressor, is a natural gas engine. A diesel engine could also be used. The difference between a natural gas engine oil and diesel engine oil is primarily in the amount of antiwear additive and the amount and types of detergent additives used. A rust and oxidation (R&O)-inhibited oil or an antiwear (zinc containing) oil could also be used. The oil viscosity used in the compressor crankcase is typically an SAE 30 (ISO 100) or SAE 40 (ISO 150) grade.

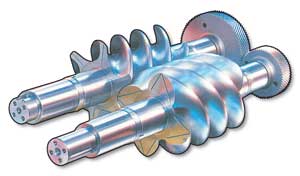

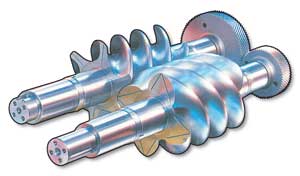

Figure 2. Pair of Rotors from a Screw Compressor

(Source: Aerzen USA, Coatesville, PA)

The compressor cylinders and rod pressure-packing oil is the main focus of this section. The oil required in these units is injected into the cylinders, packings and, in some instances, into the incoming gas upstream of the suction valves.

The Lubrication System

Two main types of oil feed pumping systems are available for the cylinders and packings. Pump-to-point systems have multiple positive displacement pumps that pump oil from a small reservoir. Each pump feeds oil to one lubrication point on the compressor. Distribution block systems use one or two larger pumps to force oil through sized and sequenced valves which distribute the oil to the various lubrication points. Distribution block systems must be designed specifically for a given compressor. Once installed, only the overall flow through the entire system can be readily adjusted by the on-site operators and maintenance staff. This is a once-through application in which the oil is not recovered or recirculated.

Lubricant Composition

Lubrication of the cylinders and packings when compressing dry sales gas or pipeline gas is typically accomplished with a natural gas engine oil (NGEO) having a viscosity of an SAE 40 grade (or a heavy SAE 30), as used in the crankcase. For pressures less than 1,000 psi (7,500 kPa) this is adequate. At pressures greater than 1,200 psi (8,273 kPa), a higher viscosity oil is required and typically a special cylinder oil is used, as described below.

If the gas being compressed is a wet or sour natural gas or a solvent gas (propane and CO2), a special cylinder oil is recommended. If in doubt about the composition of the gas, it is best to assume that it is wet and use one of the special cylinder oils available.

Most compressor cylinder oils are formulated with mineral base oils and a synthetic additive or component to prevent the oil being washed-off the cylinder wall by the solvent-like action of the gas. Older technology products were compounded oils which included animal and/or vegetable fatty additives such as tallow, lard or castor oil. These older technologies were susceptible to forming deposits in the tanks and flow lines of the lubrication system, especially if stored for a long time and/or exposed to cold temperatures.

The viscosity of the oil required for the cylinders and packings in raw field or solvent gas service depends upon the specific gases being compressed and the highest discharge pressure encountered. It is common for some of these compressors to handle two or three different gases at one time in different cylinders. The cylinder with the most severe service on the compressor dictates the oil to be used, as most compressors will have only one oil injection system. For the compression of natural gas below 2,500 psi (17,000 kPa), which is common, an ISO 220 viscosity grade product or an oil with a viscosity of 250 to 280 cSt at 40°C is recommended. If the gas being compressed has significant carbon dioxide content, then a heavier ISO 320 or 460 viscosity grade may be required to compensate for the viscosity-thinning effect of the CO2 gas.

As discharge pressures increase, the cylinder oil’s viscosity must also increase. To compress natural gas at pressures from 2,500 to 4,000 psi (17,000 to 28,000 kPa), an ISO 320 or 460 grade of oil is required. At pressures greater than 4,000 psi (28,000 kPa), as used in downhole gas reinjection systems, an ISO 460 (mineral oil) product may not be sufficient and an ISO 150 or 220 synthetic polyalkyleneglycol (also known as polyglycol, PAG) may be required. These polyglycol lubricants do not absorb any of the hydrocarbon gases and therefore do not thin out or get washed off of the cylinder walls by the high-pressure gas. Polyalkyleneglycol oils are incompatible with mineral oils and therefore cannot be mixed with mineral oil-based products, including those that are typically used in the crankcase.

There is some risk of the cylinder/rod lubricant mixing with the crankcase lubricant in crosshead-type systems. These machines are designed with a wiper that pushes packing rod lubricant down the rod toward and into the crankcase. It is imperative to periodically test for contamination if incompatible crank and cylinder lubricants are used.

The low-temperature properties of the oil selected are also important as the oil must be able to flow, under gravity, from the (typically elevated) day storage tank to the oil injection pumps on the compressor at ambient temperatures at or below 0°C. Other important properties include the ability of the oil to resist coking due to heat on the valves and rods and, in sour service, the ability of the lubricant to protect against H2S corrosion.

If propane is being compressed in any cylinder on the compressor, to be used as a refrigerant within the plant, an oil with good low-temperature properties is required. This is necessary to allow the oil to spread on the cylinder walls at the coldest propane suction temperature encountered. Propane also dissolves into the oil on the cylinder walls and lowers the oil viscosity. Therefore, the oil selected must be heavy enough to protect all the cylinders at the most severe conditions encountered throughout the compressor.

Oil Injection Rates

Determining the oil feed rates to each cylinder and rod pressure-packing set is an important but inexact science. There are numerous methods for calculating or determining the oil feed rates to each cylinder and each packing box. Most are rough calculations that are intended to provide only a starting point for setting the oil injection rates. It is important for the user/engineer to understand the intended purpose of the specific formula being applied. Some are intended for use during the break-in period. Others assume some degree of water saturation of the gas, while others are minimum injection rates. The old method of counting drops of oil in the pump site-glass to determine actual feed rates is inaccurate. These site-glasses are useful only as a quick visual check to see if any oil is moving through the system.

Early formulas used to quantify feed rates were based on the amount of lubricant necessary to provide an oil film sufficient to cover the cylinder - piston ring contact area. One method suggests one U.S. pint per two million square feet of swept surface area. This is a simple formula to estimate feed rates (in U.S. pints per 24 hours) and could still be useful for low-pressure, plant air or dry gas applications (this formula is not intended to supercede more sophisticated methods for calculating feed rates for natural gas, CO2, high-pressure air, or similar process applications) as follows:

[ (Bore Diameter (inches) * * 2 * Stroke * RPM * 1440) / 144 ] / 2,000,000, where:

* 2 * Stroke * RPM * 1440) / 144 ] / 2,000,000, where:

Bore Diameter = Cylinder internal diameter or rod external diameter (for low Ps) in inches Stroke = Cylinder stroke or travel in inches

Ps) in inches Stroke = Cylinder stroke or travel in inches

RPM = Motor speed (piston cycle speed assuming no speed reduction or increase from the motor)

A simplified formula was devised by Ingersoll Rand (now Dresser-Rand), and is as follows:

Bore Diameter * Stroke * Speed * / 31,800 = Pints per 24 hours

More recently, some original equipment manufacturers (OEMs) have developed plots and mathematical calculations that take more factors into account, including discharge pressure, gas composition and degree of liquid saturation.

The system engineer begins to estimate feed volumes by calculating feed quantities for all cylinders and piston rods. The oil feed rates to the main rod packings are calculated using the same formula as used for the cylinders except that the diameter of the rod is used instead of the bore of the cylinder. Auxiliary rod packings are usually supplied at half of the rate of the main packings.

Therefore, very roughly, a typical cylinder and packing consumption rate for an entire four-cylinder, multistage unit will be approximately 12 to 30 U.S. pints (5 to 15 liters) per 24-hour operating period.

Once the rate per cylinder or rod packing is estimated, then the next step is to divide the quantity required into the actual number of injection pumps or ports available in a cylinder or packing assembly.

During the break-in period, the oil volume should be increased, either by using a formula designed for break-in periods or by injecting 1.5 to 3 times the normal operating calculated value.

Underlubrication will result in heat and wear. Overlubrication may result in valve deposits and breakage problems plus hydrocarbon contamination of processes downstream of the compressor and premature failure of the packings.

Final Inspection

There is obviously more that could and should be considered, such as including coolant temperatures, temperature differentials between the coolant and the suction gas, gas filtration quality, risk for recompression due to discharge value plugging or malfunction, and output temperatures.

Individual system variations require the system engineer to follow up hard calculations by periodically shutting down the unit, pulling suction or discharge valves and inspecting the oil film on the cylinder wall and buildup of oil in pockets or buildup of deposits on discharge valve surfaces.

A triple layer of cigarette wrapping paper provides a useful guideline when whipped across the lubricated cylinder wall. If oil soaks through the three layers, then the feed rate is considered to be high. If the oil fails to soak through the first to the second layer then the rate is low. The OEM can and should provide assistance to the user in making a final determination.

However, many of the issues pertaining to lubrication of reciprocating compressors for the pipeline application would also pertain to the effective lubrication of machines for in-plant service.

Gas transmission applications are typically powered by a reciprocating engine fueled by natural gas. These compressors may be located in the field at a remote station or at the inlet to a gas plant where raw, wet (containing droplets of water or hydrocarbon) and possibly sour (containing hydrogen sulfide, H2S) natural gas is compressed.

Figure 1. High-pressure Service, Forged-steel, Double-acting Cyclinder

The packing box is water-cooled. The packing may be oil- or water-cooled by a forced circulation system for maximum heat dissipation, depending on operating pressures. Tie bolts which run perpendicular to the cylinder base pre-stress high-pressure forgings, decreasing maximum tensile stress induced by gas pressure.

(Source: Dresser-Rand, Painted Post, NY)

Compressor crankcase lubrication is relatively simple. Crankcase lubrication typically uses an oil system that is entirely separate from the compressor cylinder and rod-packing lube system. Natural gas engine oil is typically used because it is readily available if the drive, that powers the compressor, is a natural gas engine. A diesel engine could also be used. The difference between a natural gas engine oil and diesel engine oil is primarily in the amount of antiwear additive and the amount and types of detergent additives used. A rust and oxidation (R&O)-inhibited oil or an antiwear (zinc containing) oil could also be used. The oil viscosity used in the compressor crankcase is typically an SAE 30 (ISO 100) or SAE 40 (ISO 150) grade.

Figure 2. Pair of Rotors from a Screw Compressor

(Source: Aerzen USA, Coatesville, PA)

The Lubrication System

Two main types of oil feed pumping systems are available for the cylinders and packings. Pump-to-point systems have multiple positive displacement pumps that pump oil from a small reservoir. Each pump feeds oil to one lubrication point on the compressor. Distribution block systems use one or two larger pumps to force oil through sized and sequenced valves which distribute the oil to the various lubrication points. Distribution block systems must be designed specifically for a given compressor. Once installed, only the overall flow through the entire system can be readily adjusted by the on-site operators and maintenance staff. This is a once-through application in which the oil is not recovered or recirculated.

Lubricant Composition

Lubrication of the cylinders and packings when compressing dry sales gas or pipeline gas is typically accomplished with a natural gas engine oil (NGEO) having a viscosity of an SAE 40 grade (or a heavy SAE 30), as used in the crankcase. For pressures less than 1,000 psi (7,500 kPa) this is adequate. At pressures greater than 1,200 psi (8,273 kPa), a higher viscosity oil is required and typically a special cylinder oil is used, as described below.

If the gas being compressed is a wet or sour natural gas or a solvent gas (propane and CO2), a special cylinder oil is recommended. If in doubt about the composition of the gas, it is best to assume that it is wet and use one of the special cylinder oils available.

Most compressor cylinder oils are formulated with mineral base oils and a synthetic additive or component to prevent the oil being washed-off the cylinder wall by the solvent-like action of the gas. Older technology products were compounded oils which included animal and/or vegetable fatty additives such as tallow, lard or castor oil. These older technologies were susceptible to forming deposits in the tanks and flow lines of the lubrication system, especially if stored for a long time and/or exposed to cold temperatures.

The viscosity of the oil required for the cylinders and packings in raw field or solvent gas service depends upon the specific gases being compressed and the highest discharge pressure encountered. It is common for some of these compressors to handle two or three different gases at one time in different cylinders. The cylinder with the most severe service on the compressor dictates the oil to be used, as most compressors will have only one oil injection system. For the compression of natural gas below 2,500 psi (17,000 kPa), which is common, an ISO 220 viscosity grade product or an oil with a viscosity of 250 to 280 cSt at 40°C is recommended. If the gas being compressed has significant carbon dioxide content, then a heavier ISO 320 or 460 viscosity grade may be required to compensate for the viscosity-thinning effect of the CO2 gas.

As discharge pressures increase, the cylinder oil’s viscosity must also increase. To compress natural gas at pressures from 2,500 to 4,000 psi (17,000 to 28,000 kPa), an ISO 320 or 460 grade of oil is required. At pressures greater than 4,000 psi (28,000 kPa), as used in downhole gas reinjection systems, an ISO 460 (mineral oil) product may not be sufficient and an ISO 150 or 220 synthetic polyalkyleneglycol (also known as polyglycol, PAG) may be required. These polyglycol lubricants do not absorb any of the hydrocarbon gases and therefore do not thin out or get washed off of the cylinder walls by the high-pressure gas. Polyalkyleneglycol oils are incompatible with mineral oils and therefore cannot be mixed with mineral oil-based products, including those that are typically used in the crankcase.

There is some risk of the cylinder/rod lubricant mixing with the crankcase lubricant in crosshead-type systems. These machines are designed with a wiper that pushes packing rod lubricant down the rod toward and into the crankcase. It is imperative to periodically test for contamination if incompatible crank and cylinder lubricants are used.

The low-temperature properties of the oil selected are also important as the oil must be able to flow, under gravity, from the (typically elevated) day storage tank to the oil injection pumps on the compressor at ambient temperatures at or below 0°C. Other important properties include the ability of the oil to resist coking due to heat on the valves and rods and, in sour service, the ability of the lubricant to protect against H2S corrosion.

If propane is being compressed in any cylinder on the compressor, to be used as a refrigerant within the plant, an oil with good low-temperature properties is required. This is necessary to allow the oil to spread on the cylinder walls at the coldest propane suction temperature encountered. Propane also dissolves into the oil on the cylinder walls and lowers the oil viscosity. Therefore, the oil selected must be heavy enough to protect all the cylinders at the most severe conditions encountered throughout the compressor.

Oil Injection Rates

Determining the oil feed rates to each cylinder and rod pressure-packing set is an important but inexact science. There are numerous methods for calculating or determining the oil feed rates to each cylinder and each packing box. Most are rough calculations that are intended to provide only a starting point for setting the oil injection rates. It is important for the user/engineer to understand the intended purpose of the specific formula being applied. Some are intended for use during the break-in period. Others assume some degree of water saturation of the gas, while others are minimum injection rates. The old method of counting drops of oil in the pump site-glass to determine actual feed rates is inaccurate. These site-glasses are useful only as a quick visual check to see if any oil is moving through the system.

[ (Bore Diameter (inches) *

Bore Diameter = Cylinder internal diameter or rod external diameter (for low

RPM = Motor speed (piston cycle speed assuming no speed reduction or increase from the motor)

A simplified formula was devised by Ingersoll Rand (now Dresser-Rand), and is as follows:

Bore Diameter * Stroke * Speed * / 31,800 = Pints per 24 hours

More recently, some original equipment manufacturers (OEMs) have developed plots and mathematical calculations that take more factors into account, including discharge pressure, gas composition and degree of liquid saturation.

The system engineer begins to estimate feed volumes by calculating feed quantities for all cylinders and piston rods. The oil feed rates to the main rod packings are calculated using the same formula as used for the cylinders except that the diameter of the rod is used instead of the bore of the cylinder. Auxiliary rod packings are usually supplied at half of the rate of the main packings.

Therefore, very roughly, a typical cylinder and packing consumption rate for an entire four-cylinder, multistage unit will be approximately 12 to 30 U.S. pints (5 to 15 liters) per 24-hour operating period.

Once the rate per cylinder or rod packing is estimated, then the next step is to divide the quantity required into the actual number of injection pumps or ports available in a cylinder or packing assembly.

During the break-in period, the oil volume should be increased, either by using a formula designed for break-in periods or by injecting 1.5 to 3 times the normal operating calculated value.

Underlubrication will result in heat and wear. Overlubrication may result in valve deposits and breakage problems plus hydrocarbon contamination of processes downstream of the compressor and premature failure of the packings.

Final Inspection

There is obviously more that could and should be considered, such as including coolant temperatures, temperature differentials between the coolant and the suction gas, gas filtration quality, risk for recompression due to discharge value plugging or malfunction, and output temperatures.

Individual system variations require the system engineer to follow up hard calculations by periodically shutting down the unit, pulling suction or discharge valves and inspecting the oil film on the cylinder wall and buildup of oil in pockets or buildup of deposits on discharge valve surfaces.

A triple layer of cigarette wrapping paper provides a useful guideline when whipped across the lubricated cylinder wall. If oil soaks through the three layers, then the feed rate is considered to be high. If the oil fails to soak through the first to the second layer then the rate is low. The OEM can and should provide assistance to the user in making a final determination.

![Validate my Atom 1.0 feed [Valid Atom 1.0]](valid-atom.png)